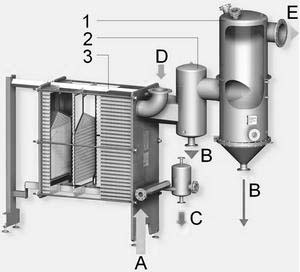

Plate evaporators

A = Product B = Concentrate C = Condensate D = Heating steam E = Vapour 1 = Main separator 2 = Pre-separator 3 = Plate calandria

¡ª¡ªDesign

Plate heat exchanger, separator. A plate-and-frame configuration adopts special plates, with alternate product and heating channels. The plates are sealed by gaskets located within specially designed slots that need not adhesives.

¡ª¡ªOperation

Product and heating media are transferred in counterflow through their relevant passages. Defined plate distances in conjunction with special plate shapes generate strong turbulence, resulting in optimum heat transfer.

Intensive heat transfer causes the product to boil while the vapour formed drives the residual liquid, as a rising film, into the vapour duct of the plate package. Residual liquid and vapours are separated in the downstream centrifugal separator. The wide inlet duct and the upward movement ensure optimum distribution over the total cross-section of the heat exchanger.

¡ª¡ªParticular features

Easy installation ¨C due to pre-assembled, transportable construction units.

Flexible evaporation rates ¨C by adding or removing plates.

Easy maintaining and cleaning ¨C as plate packages can be easily opened.

¡ª¡ªFields of application

For distillation under a smaller temperature difference.

For liquids with no tendency to fouling.