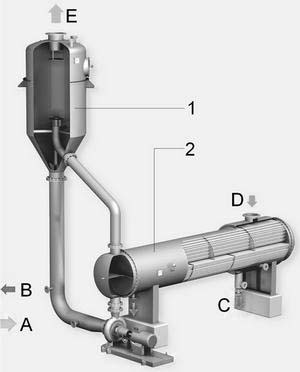

Forced circulation evaporators

A = Product B = Concentrate C = Condensate D = Heating steam E = Vapour 1 = Flash vessel/separator 2 = Heat exchanger

¡ª¡ªDesign

Horizontal or vertical shell-and-tube heat exchanger or plate heat exchanger, with flash vessel/separator and circulation pump.

¡ª¡ªOperation

The liquid is circulated through the heat exchanger by means of a circulation pump, where it is superheated at an elevated pressure, higher than its normal boiling pressure. When entering the separator, the pressure in the liquid is rapidly reduced resulting in some of the liquid being flashed, or rapidly boiled off.

Since liquid circulation is maintained, the flow velocity in the tubes and the liquid temperature can be controlled to suit the product requirements of the pre-selected temperature difference.

¡ª¡ªParticular features

Less foul ¨C boiling/evaporation will not take place on the heating surfaces, but in the separator. Fouling due to incrustation and precipitation in the calandria is therefore minimised.

Optimised heat exchange surface ¨C flow velocity in the tubes determined by the circulation pump.

¡ª¡ªFields of application

Liquids with a high tendency for fouling, highly viscous liquids, as the high concentration step in multiple-effect evaporation plants.

Forced circulation evaporators are suited as crystallising evaporators for saline solutions.