Extraction column

——Design

The multiple continuous extraction adopts a column equipment named as extraction column. Its internal structure uses gravity or mechanical action to break a liquid into droplets, disperses the droplets into another continuous liquid, and performs the liquid-liquid extraction. The extraction column has many types of structures, it can be divided into different types according to the mixed form of solvent and feed solution as well as the structure of column plate.

We provided you with rotating disc extraction column, packed extraction column, and reciprocating plate column

We provided you with rotating disc extraction column, packed extraction column, and reciprocating plate column.

Packed extraction column |

|

Reciprocating plate column |

|

Rotating disc extraction column |

|

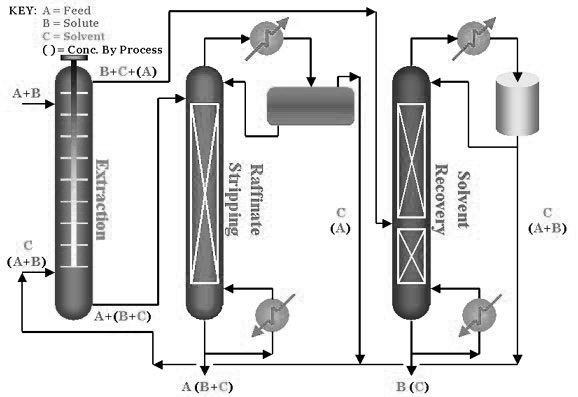

——Operation process

General conventional process

——Particular features

1. The rotating disc, sieve plate, fixed ring and ring spacing are carefully designed by our professional technicians to obtain a better extraction effect.

2. When an accurate experiment document and data is required, the effects of flux of different extract liquors and different stirring speed on the extraction efficiency can be measured with the extraction equipment.

3. The continuous operation can be realized by both the experimental extraction device and the production scale extraction device.

4. The extraction column has a prominent extraction effect on the compound with high viscosity and with temperature-sensitive component.

5. The accurate measured flow of feeding and discharging can be realized through high-precision metering pump.